Protein Powder Processing Methods Explained

Protein powder processing methods describe the steps used to turn raw protein sources into stable, usable powder ingredients. These methods focus on separating, concentrating, and preparing protein for consistent formulation rather than changing what protein is.

This article explains common protein powder processing methods using clear, foundational language. The emphasis is on structure and production steps, not outcomes, performance, or recommendations.

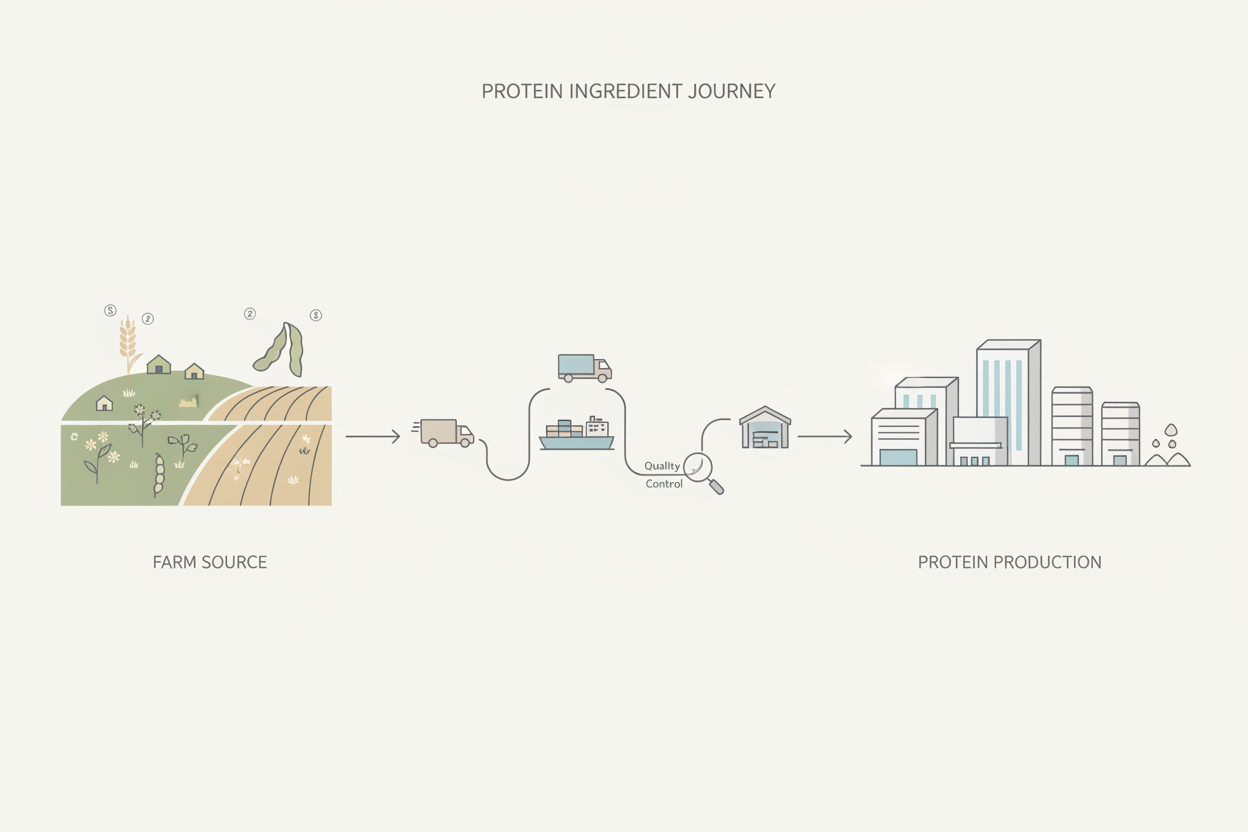

Processing Begins After Raw Material Preparation

Protein powder processing starts after raw materials are prepared.

Raw protein sources are cleaned and mechanically prepared to allow protein to be accessed and separated. This preparation step supports later processing stages but does not alter protein itself.

From this point forward, processing focuses on separation and refinement.

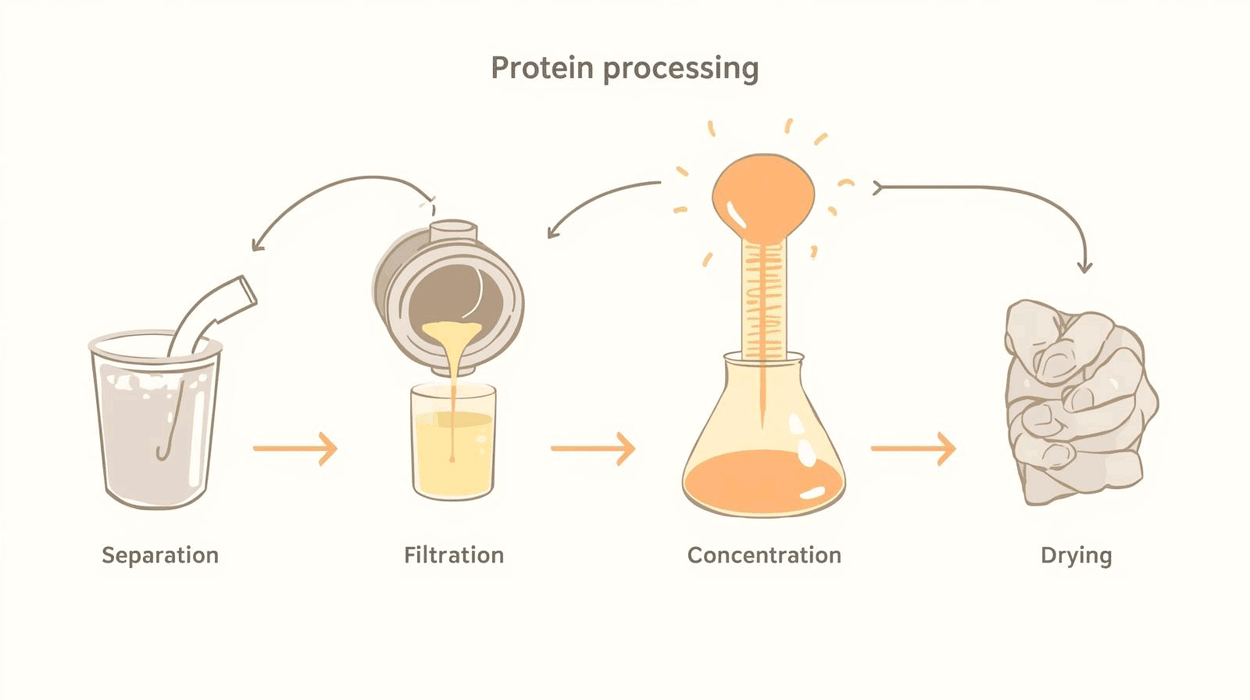

Separation and Filtration Methods

Separation is a core step in protein powder processing.

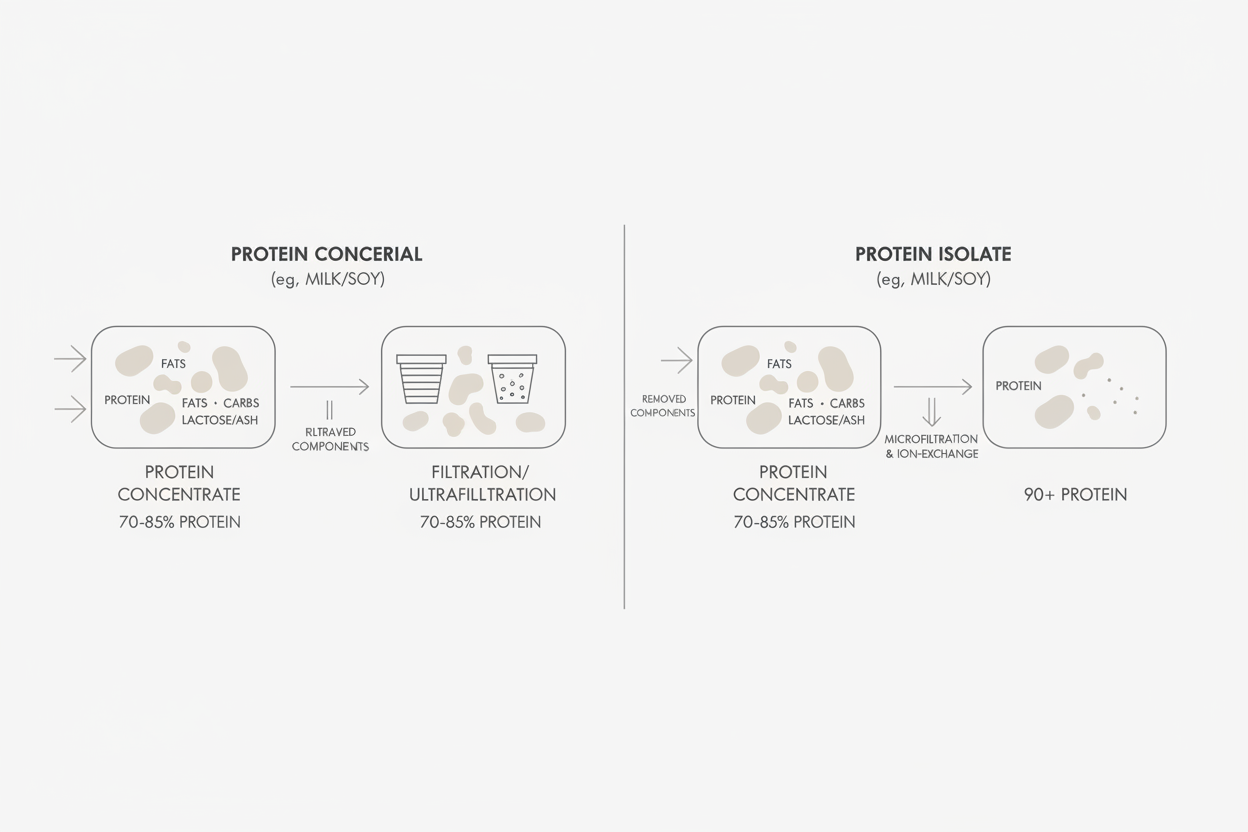

Liquid based separation methods are commonly used to isolate protein from other naturally occurring components. Filtration techniques allow protein rich portions to be retained while smaller molecules pass through.

Multiple filtration passes may be used depending on the desired protein concentration and ingredient characteristics.

Concentration Through Repeated Processing

Protein concentration increases through repeated separation steps.

As non protein components are removed, the proportion of protein in the ingredient increases. This process determines whether the final ingredient is classified as a concentrate, isolate, or blend.

Concentration reflects processing depth rather than changes to amino acid structure.

Drying and Powder Formation

Once protein has been separated and concentrated, it is dried.

Drying removes moisture and converts protein into a powder form that is easier to store, transport, and use in finished products. Spray drying and similar methods are commonly used to create consistent particle size.

Drying stabilizes the ingredient without changing its fundamental composition.

Processing Influences Physical Characteristics

Processing methods influence how protein powder behaves physically.

Processing can affect:

-

particle size

-

solubility

-

texture

-

flow characteristics

These properties matter for manufacturing and formulation but do not change protein’s role as a source of amino acids.

Standardization and Quality Control

Protein powder processing includes standardization steps.

Quality control checks verify protein content, moisture levels, and batch consistency. These steps help ensure that protein powder ingredients meet defined specifications before entering the supply chain.

Standardization supports reliability rather than altering biological function.

How This Fits Into Protein Fundamentals

Protein Fundamentals explains how protein moves from source to use.

Understanding processing methods provides context for ingredient form, consistency, and behavior without shifting into evaluation or claims. This topic supports later discussions about formulation and digestibility within Nutrition Foundations.

The explanation remains focused on production and structure.

Part of the Nutrition Foundations Series

This article is part of our Nutrition Foundations series, where we explain how different macronutrients are digested and used by the body.

👉 Visit the Nutrition Foundations hub to explore more articles in this series.

Related Articles in This Series

Frequently Asked Questions

Q: Do processing methods change protein itself

A: Processing focuses on separation and drying rather than altering protein structure.

Q: Are all protein powders processed the same way

A: No. Processing methods vary by protein source and desired ingredient characteristics.

Q: Does processing affect amino acids

A: Processing concentrates protein but does not change amino acid composition.

Q: Is drying required for protein powders

A: Drying is used to create stable, usable powder form.

Q: Does processing add ingredients

A: This article focuses on protein separation and preparation rather than formulation additives.

Q: Does this article compare processing quality

A: No. It explains processing methods without evaluation.